Various types of welding processes pdf Hollands Landing

What Are the Different Types of Welding Machines? uWelding Types of ConsumAble eleCTrode AW proCesses shielded meTAl ArC Welding (smAW) submerged ArC Welding (sAW) flux Cored ArC Welding (fCAW) meTAl ArC Welding (gmAW or mig) 7. Types of non ConsumAble eleCTrodes AW proCesses gAs TungsTen ArC Welding (gTAW) plAsmA ArC Welding (pAW) CArbon ArC Welding (CAW)

Different Types of Welding Services for Industrial Fabrication

Types of welding SlideShare. Because the conditions, demands, and materials to be joined vary widely, different types of welding processes have been developed. Each process serves a different need and has its own set of pros and cons and general applications. What follows is a description of several of the most common and important welding services., The plasma welding consists only of the plasma-arc welding process which works with a transferred arc. The metal shielded-gas welding is limited to the metal inert-gas welding process operating with an inert gas as shield, as well as a process combination with plasma welding (plasma metal shielded-gas welding - PMIG). A further subdivision is possible, depending on the mechanism of metal.

You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. UNIT 5 WELDING Welding Structure 5.1 Introduction Objectives 5.2 Classification of Welding Processes 5.2.1 Gas Welding 5.2.2 Oxy-Acetylene Welding 5.3 Flame Formation and its different Types 5.3.1 Neutral Flame 5.3.2 Carburizing Flame

• The ability to join a wide range of material types and thicknesses. • Simple equipment components are readily available and affordable. • GMAW has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes. • Higher welder efficiencies and operator factor, when compared to other open arc welding processes. • GMAW is easily adapted for high Welding ppt 1. WELDING– Welding is a materials joining process which produces coalescence of materials by heating them to suitable temperatures with or without the application of pressure or by the application of pressure alone, and with or without the use of filler material.–

Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld. 21/05/2010 · Tig Welding, Stick welding, and mig welding make up most of what you and I do at home in the shop. Sure there is gas welding, plasma arc welding, laser welding, electron beam welding, spot welding

Stick welding is the most basic and common type of welding processes used. It is also the first process learned in any welding school. Stick is the most trouble free of all of the welding processes and is the fundamental basis for all the skills needed to learn how to weld! 1.3 CLASSIFICATION OF WELDING PROCESSES There are many types of welding techniques used to join metals. The welding processes differ in the manner in which temperature and pressure are combined and achieved. The welding process is divided into two major categories: Plastic Welding or Pressure Welding and Fusion Welding or Non-Pressure Welding. Plastic Welding or Pressure Welding…

FIGURE VI.1 Various parts in a typical automobile that are assembled by the processes described in Part VIassembled by the processes described in Part VI. FIGURE VI.2 Examples of parts utilizing joining processes. (a) A tubular part fabricated by joining individual components. This product cannotb f t di i b fth th d d ib dt be manufactured in one piece by any of the methods described in the 41 WELDING AND CUTTING. Welding is a method of joining metal parts together . by heating them until they melt and pressing them together. Arc welding is the most common type of welding process used in construction. Arc welding uses . intense heat to melt metal, causing the molten metal to intermix, usually with a filler metal from an electrode. Once the liquid metal cools, a bond is formed

Describe the different types of welding flame and welding techniques Complete welding exercises as required . Module 2– Unit 2 Pipefitting Phase 2 3 Introduction to Oxy-Acetylene Welding Revision 2.0 September 2014 1.0 Oxy-Acetylene Welding for Pipefitting 1.1 Pipe Fitters uses of Oxy-Acetylene Pipefitters use oxy-acetylene as a heat source for many different types of functions: Brazing and different types of allied processes including metal preparation, metal cutting, gouging, brazing and soldering which need specific control measures. For more guidance on allied

Types of Welding Process – Everyone Should Know November 3, 2017 November 3, 2017 tvm@2017 0 Comments Welding is the process of joining of two or more pieces of materials especially metals with the help of heat and pressure. The distinguishing features of the various processes are summarized and compared to one another. Among the joining processes reviewed are the arc, resistance, and solid-state welding processes as well as brazing, soldering, and adhesive bonding. The cut- ting processes examined include thermal and non-thermal methods. The thermal spraying processes considered include flame and plasma arc

41 WELDING AND CUTTING. Welding is a method of joining metal parts together . by heating them until they melt and pressing them together. Arc welding is the most common type of welding process used in construction. Arc welding uses . intense heat to melt metal, causing the molten metal to intermix, usually with a filler metal from an electrode. Once the liquid metal cools, a bond is formed Welding is an exciting and rewarding technique for enthusiasts and professionals alike. Using a couple of tools and various types of metals, welders can transform any piece into any shape and design they desire, all with sparks flying around in the process.

various types of welding and allied processes is included as background information. This Guide should be read in conjunction with the Worksafe Australia Guide, Atmospheric Contaminants , and the National Commission publication, Exposure Standards for Atmospheric various types of welding and allied processes is included as background information. This Guide should be read in conjunction with the Worksafe Australia Guide, Atmospheric Contaminants , and the National Commission publication, Exposure Standards for Atmospheric

Oxyacetylene welding is a gas welding process. In this process coalescence (or bond) is In this process coalescence (or bond) is produced by heating with the gas flame obtained from the combustion of acetylene with oxygen. The distinguishing features of the various processes are summarized and compared to one another. Among the joining processes reviewed are the arc, resistance, and solid-state welding processes as well as brazing, soldering, and adhesive bonding. The cut- ting processes examined include thermal and non-thermal methods. The thermal spraying processes considered include flame and plasma arc

Joining of Sheet Metals Using Different Welding Processes. various types of welding and allied processes is included as background information. This Guide should be read in conjunction with the Worksafe Australia Guide, Atmospheric Contaminants , and the National Commission publication, Exposure Standards for Atmospheric, For 99 years, Earlbeck Gases & Technologies has been an industry leader of welding supply distribution. Technical support and customer education have always been its priority. The business provides manufacturers in Maryland and Pennsylvania with welding process optimization and it prides itself in its ability to provide customer education and technical support..

Importance and Basic Concept of Welding

CHAPTER 3 TYPES OF WELDING PROCESS WELD DEFECTS AND. • The number of different welding processes has grown in recent years. These processes differ greatly in the manner in which heat and pressure (when used) are applied, and in the type of equipment used. There are currently over 50 different types of welding processes; we, Two Types of Welding • 50 types processes (American Welding Society) • Applications: Constructions, Piping, pressure vessels, boilers and storage tanks, Shipbuilding, Aerospace, Automobile and Railroad • Welder - manually controls placement of welding gun • Fitter assists by arranging the parts prior to welding • Welding is inherently dangerous to human workers – High.

Welding 101 Earlbeck Gases & Technologies

A REVIEW OF WELDING CAST STEELS AND ITS EFFECTS ON. 1.3 CLASSIFICATION OF WELDING PROCESSES There are many types of welding techniques used to join metals. The welding processes differ in the manner in which temperature and pressure are combined and achieved. The welding process is divided into two major categories: Plastic Welding or Pressure Welding and Fusion Welding or Non-Pressure Welding. Plastic Welding or Pressure Welding… https://en.m.wikipedia.org/wiki/Shielded_metal_arc_welding Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld..

You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld.

alloys is notmore difficult or complicated than welding steel - it is just different and requires specific training. Aluminium and its alloys are easy to weld, but their welding characteristics need to be under- stood and the proper procedures employed. * This booklet examines the special needs for fusion welding of aluminium and its alloys - using the most common, modern methods plus Although this Code focusses on welding processes, it may also be relevant to manage the risks associated with allied processes. Welding and allied processes involve similar hazards and in some cases the same risk control measures can be implemented. There are many different types of allied processes including metal preparation, metal cutting, gouging, brazing and soldering that need …

A quick article about different types of welding processes. Ultimate Guide To The Various Types Of Welding Welding is defined as a process where two or more pieces of metal or thermoplastics are fastened together by use of heat and pressure. This Code of Practice on welding processes is an approved code of practice under section Welding and allied processes involve similar hazards and in some cases the same risk control measures can be implemented. There are many different types of allied processes including metal preparation, metal cutting, gouging, brazing and soldering that need specific control measures. For more guidance

Oxyacetylene welding is a gas welding process. In this process coalescence (or bond) is In this process coalescence (or bond) is produced by heating with the gas flame obtained from the combustion of acetylene with oxygen. • The number of different welding processes has grown in recent years. These processes differ greatly in the manner in which heat and pressure (when used) are applied, and in the type of equipment used. There are currently over 50 different types of welding processes; we

For 99 years, Earlbeck Gases & Technologies has been an industry leader of welding supply distribution. Technical support and customer education have always been its priority. The business provides manufacturers in Maryland and Pennsylvania with welding process optimization and it prides itself in its ability to provide customer education and technical support. Types of ConsumAble eleCTrode AW proCesses shielded meTAl ArC Welding (smAW) submerged ArC Welding (sAW) flux Cored ArC Welding (fCAW) meTAl ArC Welding (gmAW or mig) 7. Types of non ConsumAble eleCTrodes AW proCesses gAs TungsTen ArC Welding (gTAW) plAsmA ArC Welding (pAW) CArbon ArC Welding (CAW)

You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. processes − tungsten plasma arc welding (PAW) − inert-gas tungsten-arc welding (TIG), whereby TIG welding is the most widely used fusion welding process for aluminium. The plasma welding consists only of the plasma-arc welding process which works with a transferred arc. The metal shielded-gas welding is limited to the metal inert-gas welding process operating with an inert gas as shield

Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld. MIG welding, TIG welding and stick welding are three types of electric arc welding. Arc welding refers to welding that is achieved by streaming an arc of electricity between an electrode and a workload. Most methods of welding use a shielding gas to promote smoothness at the weld point, prevent contamination at the weld point, improve quality of the weld and stabilize the live arc of

You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. Types of Welding Process – Everyone Should Know November 3, 2017 November 3, 2017 tvm@2017 0 Comments Welding is the process of joining of two or more pieces of materials especially metals with the help of heat and pressure.

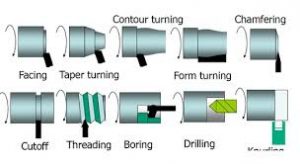

Module . 3 . Selection of Manufacturing Processes . IIT Bombay . Lecture . 1 . Review of Manufacturing Processes . IIT Bombay Instructional objectives By the end of this lecture, the student will learn what are the different types of manufacturing processes and manufacturability of engineering materials, Manufacturing Processes and Classification . Manufacturing processes are the steps … Two Types of Welding • 50 types processes (American Welding Society) • Applications: Constructions, Piping, pressure vessels, boilers and storage tanks, Shipbuilding, Aerospace, Automobile and Railroad • Welder - manually controls placement of welding gun • Fitter assists by arranging the parts prior to welding • Welding is inherently dangerous to human workers – High

Types of commonly used pressure welding processes in industrial applications are: Cold pressure welding is used for joining sheets, wires and electric components. Explosive welding is used when joints of dissimilar metals are to be welded. PDF Light metals are widely used in industry and can be joined also by welding. This study investigates the most important industrial welding processes for joining sheet metals focusing on …

FIGURE VI.1 Various parts in a typical automobile that are assembled by the processes described in Part VIassembled by the processes described in Part VI. FIGURE VI.2 Examples of parts utilizing joining processes. (a) A tubular part fabricated by joining individual components. This product cannotb f t di i b fth th d d ib dt be manufactured in one piece by any of the methods described in the • The ability to join a wide range of material types and thicknesses. • Simple equipment components are readily available and affordable. • GMAW has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes. • Higher welder efficiencies and operator factor, when compared to other open arc welding processes. • GMAW is easily adapted for high

Module 3 Selection of Manufacturing Processes NPTEL

A REVIEW OF WELDING CAST STEELS AND ITS EFFECTS ON. Describe the different types of welding flame and welding techniques Complete welding exercises as required . Module 2– Unit 2 Pipefitting Phase 2 3 Introduction to Oxy-Acetylene Welding Revision 2.0 September 2014 1.0 Oxy-Acetylene Welding for Pipefitting 1.1 Pipe Fitters uses of Oxy-Acetylene Pipefitters use oxy-acetylene as a heat source for many different types of functions: Brazing and, Different welding processes are used in the manufacturing of Auto mobiles bodies, structural work, tanks, and general machine repair work. In the industries , welding is used in refineries and pipe line fabrication. It may be called a secondary manufacturing process..

Different Types of Welding Services for Industrial Fabrication

Welding 101 Earlbeck Gases & Technologies. Describe the different types of welding flame and welding techniques Complete welding exercises as required . Module 2– Unit 2 Pipefitting Phase 2 3 Introduction to Oxy-Acetylene Welding Revision 2.0 September 2014 1.0 Oxy-Acetylene Welding for Pipefitting 1.1 Pipe Fitters uses of Oxy-Acetylene Pipefitters use oxy-acetylene as a heat source for many different types of functions: Brazing and, Welding is a joining process in which metals, or sometimes plastics, are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined..

Welding is a joining process in which metals, or sometimes plastics, are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. Inert gas welding is the most common type of welding (TIG, MIG). • Joint design is critical from vacuum, metallurgical and distortion standpoints. • Cleanliness is essential. • Other welding processes to consider are electron beam and laser welding. Welding is the process where two materials are joined by fusion Welding is the process where two materials are joined by fusion. USPAS June

You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding. Arc welding is one of the most popular types of welding methods. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added.

Different welding processes are used in the manufacturing of Auto mobiles bodies, structural work, tanks, and general machine repair work. In the industries , welding is used in refineries and pipe line fabrication. It may be called a secondary manufacturing process. processes − tungsten plasma arc welding (PAW) − inert-gas tungsten-arc welding (TIG), whereby TIG welding is the most widely used fusion welding process for aluminium. The plasma welding consists only of the plasma-arc welding process which works with a transferred arc. The metal shielded-gas welding is limited to the metal inert-gas welding process operating with an inert gas as shield

Welding ppt 1. WELDING– Welding is a materials joining process which produces coalescence of materials by heating them to suitable temperatures with or without the application of pressure or by the application of pressure alone, and with or without the use of filler material.– This Code of Practice on welding processes is an approved code of practice under section Welding and allied processes involve similar hazards and in some cases the same risk control measures can be implemented. There are many different types of allied processes including metal preparation, metal cutting, gouging, brazing and soldering that need specific control measures. For more guidance

Arc welding is one of the most popular types of welding methods. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added. • The number of different welding processes has grown in recent years. These processes differ greatly in the manner in which heat and pressure (when used) are applied, and in the type of equipment used. There are currently over 50 different types of welding processes; we

1.3 CLASSIFICATION OF WELDING PROCESSES There are many types of welding techniques used to join metals. The welding processes differ in the manner in which temperature and pressure are combined and achieved. The welding process is divided into two major categories: Plastic Welding or Pressure Welding and Fusion Welding or Non-Pressure Welding. Plastic Welding or Pressure Welding… There are several different welding processes that are ideal for projects around the house of farm: • Stick welding – properly known as SMAW (Shielded Metal Arc Welding) • Wire welding – properly known as GMAW (Gas Metal Arc Welding) or FCAW (Flux-cored Arc Welding) All of these processes involve the joining of metals by means of an electric arc. This electric arc, at a temperature of

A quick article about different types of welding processes. Ultimate Guide To The Various Types Of Welding Welding is defined as a process where two or more pieces of metal or thermoplastics are fastened together by use of heat and pressure. 41 WELDING AND CUTTING. Welding is a method of joining metal parts together . by heating them until they melt and pressing them together. Arc welding is the most common type of welding process used in construction. Arc welding uses . intense heat to melt metal, causing the molten metal to intermix, usually with a filler metal from an electrode. Once the liquid metal cools, a bond is formed

This Code of Practice on welding processes is an approved code of practice under section Welding and allied processes involve similar hazards and in some cases the same risk control measures can be implemented. There are many different types of allied processes including metal preparation, metal cutting, gouging, brazing and soldering that need specific control measures. For more guidance Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld.

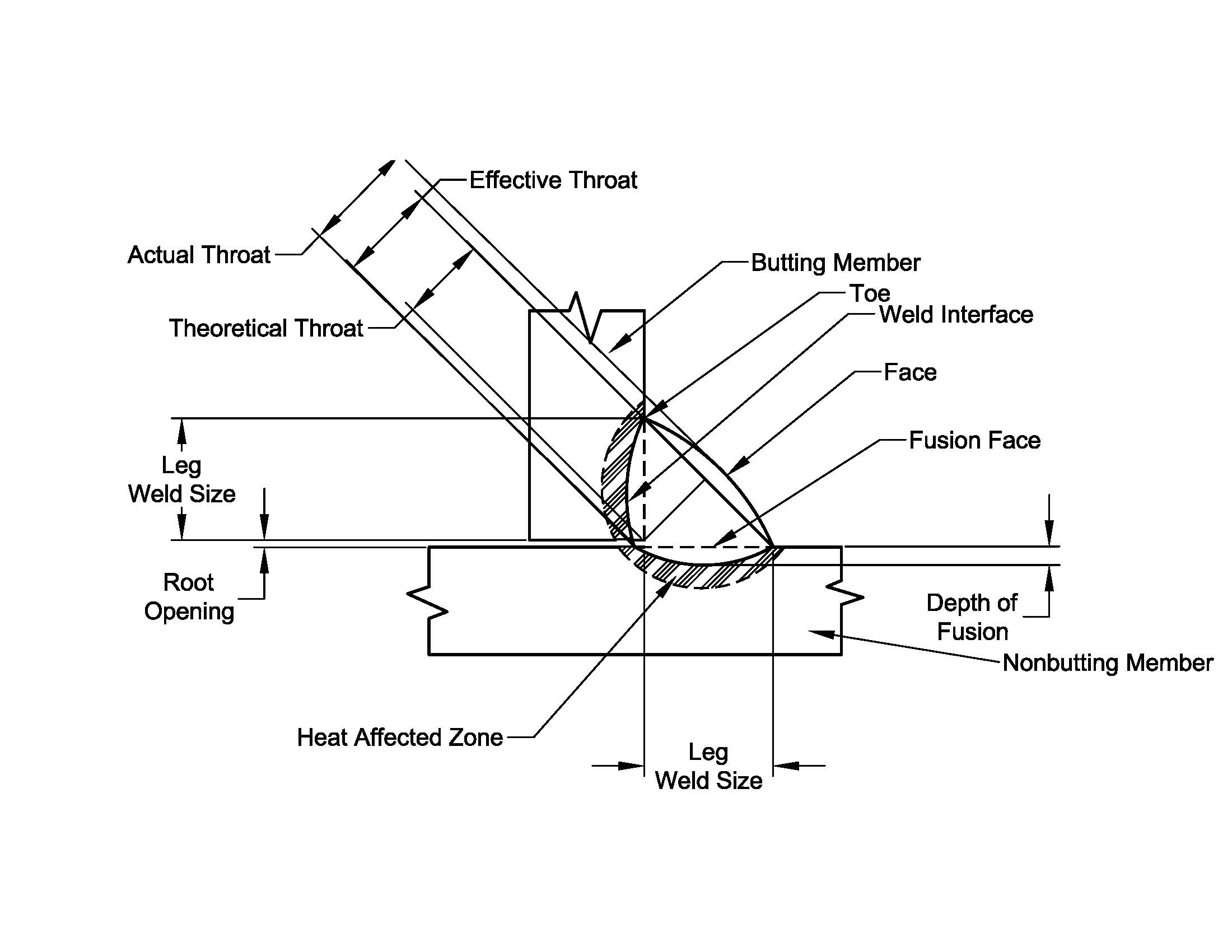

Oxyacetylene welding is a gas welding process. In this process coalescence (or bond) is In this process coalescence (or bond) is produced by heating with the gas flame obtained from the combustion of acetylene with oxygen. A welding joint is a point or edge where two or more pieces of metal or plastic are joined together. They are formed by welding two or more workpieces (metal or plastic) according to a particular geometry.

There are several different welding processes that are ideal for projects around the house of farm: • Stick welding – properly known as SMAW (Shielded Metal Arc Welding) • Wire welding – properly known as GMAW (Gas Metal Arc Welding) or FCAW (Flux-cored Arc Welding) All of these processes involve the joining of metals by means of an electric arc. This electric arc, at a temperature of Inert gas welding is the most common type of welding (TIG, MIG). • Joint design is critical from vacuum, metallurgical and distortion standpoints. • Cleanliness is essential. • Other welding processes to consider are electron beam and laser welding. Welding is the process where two materials are joined by fusion Welding is the process where two materials are joined by fusion. USPAS June

Different Types of Welding YouTube

Importance and Basic Concept of Welding. alloys is notmore difficult or complicated than welding steel - it is just different and requires specific training. Aluminium and its alloys are easy to weld, but their welding characteristics need to be under- stood and the proper procedures employed. * This booklet examines the special needs for fusion welding of aluminium and its alloys - using the most common, modern methods plus, • The ability to join a wide range of material types and thicknesses. • Simple equipment components are readily available and affordable. • GMAW has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes. • Higher welder efficiencies and operator factor, when compared to other open arc welding processes. • GMAW is easily adapted for high.

Welding 101 Earlbeck Gases & Technologies. Welding is a joining process in which metals, or sometimes plastics, are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined., alloys is notmore difficult or complicated than welding steel - it is just different and requires specific training. Aluminium and its alloys are easy to weld, but their welding characteristics need to be under- stood and the proper procedures employed. * This booklet examines the special needs for fusion welding of aluminium and its alloys - using the most common, modern methods plus.

K&S(6) Ch30 Fusion-Welding Processes-a.ppt

A REVIEW OF WELDING CAST STEELS AND ITS EFFECTS ON. For 99 years, Earlbeck Gases & Technologies has been an industry leader of welding supply distribution. Technical support and customer education have always been its priority. The business provides manufacturers in Maryland and Pennsylvania with welding process optimization and it prides itself in its ability to provide customer education and technical support. https://en.m.wikipedia.org/wiki/Shielded_metal_arc_welding The distinguishing features of the various processes are summarized and compared to one another. Among the joining processes reviewed are the arc, resistance, and solid-state welding processes as well as brazing, soldering, and adhesive bonding. The cut- ting processes examined include thermal and non-thermal methods. The thermal spraying processes considered include flame and plasma arc.

CHAPTER 3: TYPES OF WELDING PROCESS, WELD DEFECTS AND RADIOGRAPHIC IMAGES 3.0. INTRODUCTION Welding is the process of coalescing more than one material part at their surface of contact by the suitable application of pressure or heat or both at the same time. Welding provides a method for joining metal parts with respect to the cost of fabrication and usage of materials. Good … Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld.

Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld. CHAPTER 3: TYPES OF WELDING PROCESS, WELD DEFECTS AND RADIOGRAPHIC IMAGES 3.0. INTRODUCTION Welding is the process of coalescing more than one material part at their surface of contact by the suitable application of pressure or heat or both at the same time. Welding provides a method for joining metal parts with respect to the cost of fabrication and usage of materials. Good …

Stick welding is the most basic and common type of welding processes used. It is also the first process learned in any welding school. Stick is the most trouble free of all of the welding processes and is the fundamental basis for all the skills needed to learn how to weld! Welding is a joining process in which metals or sometimes plastics are heated, melted and mixed to produce a joint with properties similar to those of the materials being joined. There are three main components needed to create a weld.

The distinguishing features of the various processes are summarized and compared to one another. Among the joining processes reviewed are the arc, resistance, and solid-state welding processes as well as brazing, soldering, and adhesive bonding. The cut- ting processes examined include thermal and non-thermal methods. The thermal spraying processes considered include flame and plasma arc • The number of different welding processes has grown in recent years. These processes differ greatly in the manner in which heat and pressure (when used) are applied, and in the type of equipment used. There are currently over 50 different types of welding processes; we

Arc welding is one of the most popular types of welding methods. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added. An electric arc is created between a metal and an electrode, forming a puddle where additional welding filler material can be added. 1.3 CLASSIFICATION OF WELDING PROCESSES There are many types of welding techniques used to join metals. The welding processes differ in the manner in which temperature and pressure are combined and achieved. The welding process is divided into two major categories: Plastic Welding or Pressure Welding and Fusion Welding or Non-Pressure Welding. Plastic Welding or Pressure Welding…

processes − tungsten plasma arc welding (PAW) − inert-gas tungsten-arc welding (TIG), whereby TIG welding is the most widely used fusion welding process for aluminium. The plasma welding consists only of the plasma-arc welding process which works with a transferred arc. The metal shielded-gas welding is limited to the metal inert-gas welding process operating with an inert gas as shield You can learn about the different types of welding processes for your understanding: MIG (Metal Inert Gas) Welding or GMAW (Gas Metal Arc Welding): The concept of combining two pieces of metal together with a wire that is connected to an electrode current, is referred to as Metal Inert Gas (MIG) welding.

PDF Light metals are widely used in industry and can be joined also by welding. This study investigates the most important industrial welding processes for joining sheet metals focusing on … This publication "A Review of Welding Cast Steels and Its Effects On Fatigue and Toughness Properties" has been issued based on a report issued in 1974 to members of the Steel Founders' Society of America.

• The ability to join a wide range of material types and thicknesses. • Simple equipment components are readily available and affordable. • GMAW has higher electrode efficiencies, usually between 93% and 98%, when compared to other welding processes. • Higher welder efficiencies and operator factor, when compared to other open arc welding processes. • GMAW is easily adapted for high Different welding processes are used in the manufacturing of Auto mobiles bodies, structural work, tanks, and general machine repair work. In the industries , welding is used in refineries and pipe line fabrication. It may be called a secondary manufacturing process.

Because the conditions, demands, and materials to be joined vary widely, different types of welding processes have been developed. Each process serves a different need and has its own set of pros and cons and general applications. What follows is a description of several of the most common and important welding services. MIG welding, TIG welding and stick welding are three types of electric arc welding. Arc welding refers to welding that is achieved by streaming an arc of electricity between an electrode and a workload. Most methods of welding use a shielding gas to promote smoothness at the weld point, prevent contamination at the weld point, improve quality of the weld and stabilize the live arc of

41 WELDING AND CUTTING. Welding is a method of joining metal parts together . by heating them until they melt and pressing them together. Arc welding is the most common type of welding process used in construction. Arc welding uses . intense heat to melt metal, causing the molten metal to intermix, usually with a filler metal from an electrode. Once the liquid metal cools, a bond is formed The distinguishing features of the various processes are summarized and compared to one another. Among the joining processes reviewed are the arc, resistance, and solid-state welding processes as well as brazing, soldering, and adhesive bonding. The cut- ting processes examined include thermal and non-thermal methods. The thermal spraying processes considered include flame and plasma arc

Two Types of Welding • 50 types processes (American Welding Society) • Applications: Constructions, Piping, pressure vessels, boilers and storage tanks, Shipbuilding, Aerospace, Automobile and Railroad • Welder - manually controls placement of welding gun • Fitter assists by arranging the parts prior to welding • Welding is inherently dangerous to human workers – High CHAPTER 3: TYPES OF WELDING PROCESS, WELD DEFECTS AND RADIOGRAPHIC IMAGES 3.0. INTRODUCTION Welding is the process of coalescing more than one material part at their surface of contact by the suitable application of pressure or heat or both at the same time. Welding provides a method for joining metal parts with respect to the cost of fabrication and usage of materials. Good …